CEMB SHOP DYNAMIC BALANCING MACHINE - Z4500

Horizontal balancers with joint drive or belt drive for rotors from 10 kg up to 6,000 kg. The power necessary to rotate the piece to be balanced is transmitted by various means: a double cardan joint, belts that wrap around the rotor or tangential, rollers, compressed air devices and electromagnetic fields. The universal joint shaft is based on the ratio between the size of the joint and the torque value transmitted from the spin motor; hence the advantage and the greater precision of the balancing machines with variable speed drives, in which it’s possible to adapt the transmitted torque to the rotor dimension. The belt drive can give better accuracy than the cardan drive and offer the advantage of easier and faster mounting of the rotor on the balancing machine; it is particularly suitable for batch operation. In order to use a belt drive, the rotor must have at least one perfectly cylindrical section on which the belt can be fitted. Belt drive becomes a necessity when the rotor has no journal to which a cardan joint can be applied. Note that belt drives call for the presence of axial thrust stops to stop the rotor from making any dangerous movements. The two types of drive can also be used together: this solution improves machine application and makes it more practical

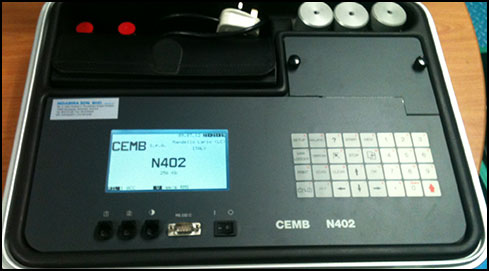

CEMB N402 On Site balancing

On site balancing is balancing a part while it is in its normal operating position at your facility; and allows

operation to resume immediately following the balancing operation. It can generally be performed on all types

of rotating machinery.

Another advantage on site balancing is that it compensates for assembly tolerances, unbalance of pulleys, gears,

coupling, and other added components of new or overhauled machinery.

Easy Laser Shaft Alignment

You have much to gain in both

time and money through having your machines aligned to correct tolerances. A well aligned machine pays for itself through lower costs

for replacement parts, less downtime and smaller electricity bills. You get a better working environment into the

bargain. Correctly aligned machines reduce the risk of expensive breakdowns and downtime.

Typical problems arising from poor machine alignment are:

Lost production time, leaking seals, increase vibration level, high enery consumption, bearing failure, shaft

breakage, coupling wear and etc.

Mechanical & Electrical Engineering MRO (Maintenance, Repair & Ovelhaul) for most type of machine

Eletrical Induction Motor

Rewind, shop repair and IEEE Standard winding Analysis Test and predictive motor circuit analysis test come with

test report.

Variable type of pumps and blower fan.

Pump refurbishment, shop/site repair service, pump efficiency/performance test and installation.

induction motor troubleshooting, service, revarnish and rewind.

Metallic Composite Coating & Lining Services To Repair, Rebuild & Resurface

Eroded/Worn Out Components Include Grit Blasting Services.

Elastomer Coasting Services

To improve pump performance efficiency and reduce wear & tear.

Mechanical seal supply, custome made seals, seal lapping & polishing and reconditioning service.

|